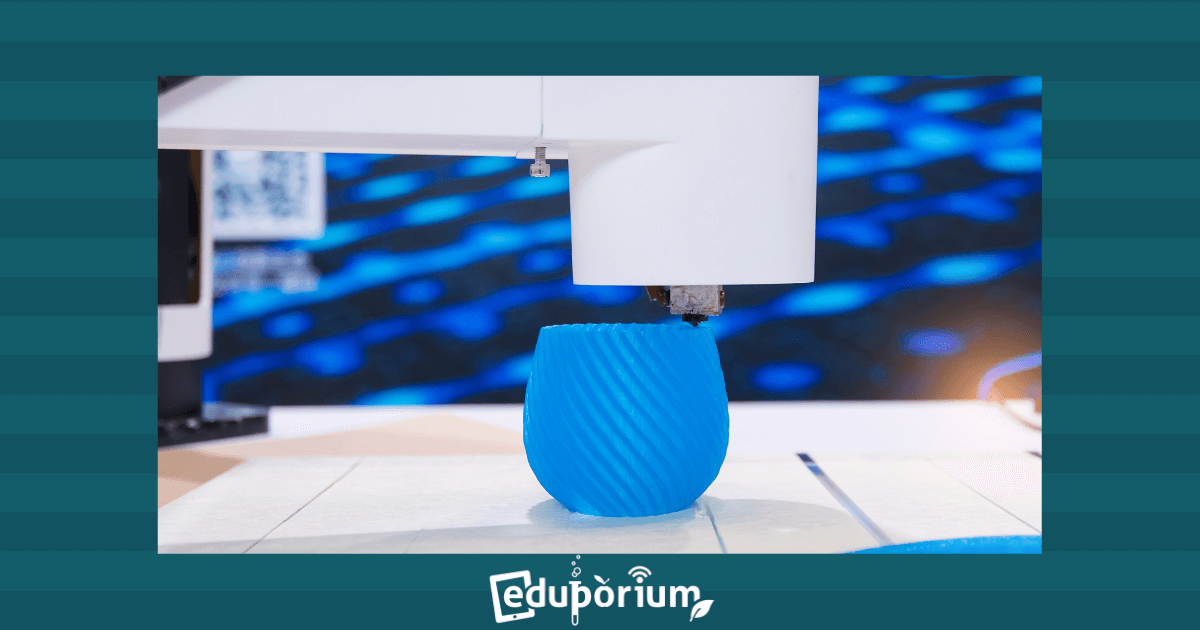

With the rise of STEM jobs and STEM education has come a renewed focus on hands-on learning. You probably already were aware of this. A big part of this hands-on learning, however, even in K-12 schools, is 3D printing. Engaging in 3D printing allows students to experience learning from brand new angles and put their creativity to use in ways that will legitimately help them prepare for their futures. Right now, scientists seem to using 3D printing for something new every day—in some industries that you would expect and others that are pretty surprising.

Air Travel

You might be thinking how can the commercial aircraft industry make use of 3D printing? Well, it’s something a bit smaller than you might be imagine. We’re not talking about entire planes being 3D printed, but rather certain parts of those planes being made by printers. And, in many cases, these parts are actually making air travel safer. Using 3D printing, manufacturers are can make parts that are both safer and stronger, ensuring the overall longevity of the planes they are added to. It doesn’t even take any kind of special approach. It’s done in the same way that students use 3D printing in their schools. They design the part they need using software and, after a few hours, they have the exact shape that’s required.

It’s also well within the realm of possibility that 3D printed parts help make planes more efficient and powerful. One part that’s now being made by 3D printers, in some cases, is the plane’s fuel nozzle. Instead of engineers welding together 20-something pieces to get the final part that they need, they can 3D print the exact shape that’s required. It’s not a foolproof science as 3D printing jet parts does come with its own set of challenges. It can sometimes be difficult to get a device into the exact shape that’s needed, so, even though they have the capabilities to create almost any shape imaginable, this can lead to many failed attempts due to the pretty huge range of possible outcomes.

This also reduces the likelihood of getting totally identical parts time and time again, but it is affordable, fairly quick, and very accessible. We know that 3D printers are widely available these days and, despite manufacturers needing some high-quality ones, they generally don’t have problems finding something that will work. In the airline industry alone, the 3D printing of plane parts has led to the creation of many new STEM-based jobs. Someone has to design the print, another person has to create it, and then, perhaps most importantly, somebody else has to test it to make sure it’s plenty safe enough to use on a plane. As things progress, software and other technologies are being created to help ensure safety and efficiency when 3D printing plane parts and the idea continues to hold a lot of promise.

Space Travel

It should come as no surprise that advances in technology have done wonders to make space travel more practical, accessible, and affordable. One of those technologies—now more than ever—is 3D printing. In fact, the more advanced 3D printing technology becomes, the more astronauts and engineers are able to accomplish in space. The idea of utilizing 3D printing technology in space travel has been on the table for some time, but fully integrating it into common building is likely to be a slow process as well as a costly one. So many things are able to be built with 3D printers, including larger objects, like cars and houses, but we are also approaching a world in which something as monumental and complex, like a rocket, can be built either partially or completely using 3D printing. It really might not be as far off as we think.

One of the advantage of 3D printing parts is the elimination of human labor needed for building them. It also makes it more affordable for companies because they obviously do not have to pay human workers. Removing human labor from the equation could potentially reduce the cost of building a full-scale rocket from around $100 million to $10 million, according to a report from PSFK. It can also significantly reduce the amount of time it takes to build a rocket from a number of months down to just one. The overall goal is to continue building full-sized and fully operational rockets while improving the efficiency and affordability tenfold.

The benefits of 3D printing are very much recognizable in all sorts of STEM industries. Like all space travel, the ultimate goal is to create rockets that contribute to the overall quality of space travel. With all of the advances space travel has already seen, the next ones could be much more affordable and attainable. As 3D printing makes the production of space vehicles more affordable, other things could soon shift into focus as well. There may be more money freed up for longer and more involved missions. Maybe civilians will have more access to space travel. The latter more so than the former is a pretty lofty dream, but, the efficiencies of modern technology can help do a lot. All in all, 3D printing should prove to be a viable option in making space travel more efficient.

3D Printing Could Soon be a Routine Part of Surgeries

So far, we’ve discussed how 3D printing can help people create parts and devices that are the exact dimensions they need in order to solve a big problem or make something a whole lot easier. Well, that is certainly a common theme in operating rooms around the world and the emergence of 3D printing as a legitimate tool has helped doctors and surgeons do just that. Some of the world’s most gifted doctors have been using similar technologies, like 3D imaging for a while now, but 3D printing is enabling them to create patient-specific models that are even more detailed. This not only helps them during the actual time in which they are performing the surgery, but in the planning stages as well. What was once used only in rare circumstances has now become a commonly relied on tool by doctors around the world.

Let’s first clarify what all this means. Though we could see this someday, we are not currently at a point in which doctors can simply press a button a print out a custom-designed nose or a heart for a patient. In the medical industry, 3D printing is more likely to help doctors and patients by providing them with a cheap, custom, and quick way to design medical devices that are made exactly to the specs of each particular patient. Perhaps the biggest impact 3D printing has made so far is in the area of prosthetics. People of all ages have gotten the chance to live more fulfilling lives because the technology has enabled the production of devices that are the exact size, weight, and shape that they need. On the inside of the body, however, 3D printing is also starting to play a small role. It’s helped create patient-specific titanium implants and could soon enable doctors to do more, like create 3D printed pacemakers and other critical medical devices in the future.

Not surprisingly, 3D printing has also helped doctors and surgeons perform their operations. A lot of the time, they are obviously doing some very complex things inside a person’s body and need highly customized tools to reach certain places and keep certain things where they are. For those reasons, traditional scalpel is no longer always a very useful surgical tool. In fact, there’s a good chance that doctors could soon start 3D printing tools specific to the surgeries each of their patients are going to be having. The best part is that 3D printers are small enough that they can be housed right in the hospitals doctors are working in and could potentially even be portable depending on their size (many are still pretty large because they have so much strength). In any case, 3D printing has helped make surgeries and doctor visits a bit more efficient for patients and could very well see continued improvements regularly.

House Construction

The technical term for 3D printing is what’s known as ‘additive manufacturing.’ You may notice the word ‘add’ in there, so what exactly does this mean? Well, basically, additive manufacturing is a process in which a machine (in this case a 3D printer) joins materials together, layer by layer, to create a single object. That’s sort of what it takes to build a house or a building, right? Since 3D printing enables engineers and architects to design and build just about anything with any set of specifications, they’re able to use this technology to (very slowly) build houses. Before you start to get too blown away, however, we’re not talking about mansions here or even what we’ve come to think of as a standard, family-sized house. They tend to be more of the single-floor, greenhouse-lookalike variety, but that’s a start.

Think of one of those tiny houses you see on TV. Those are the kinds of homes that could soon regularly be 3D printed. Just like in any industry, however, there would be some positives that come along with 3D printing homes and some negatives. The positives include greater safety, fewer hours of human labor, and decreased costs. The one glaring negative, however, is that it could take jobs away from construction workers. This isn’t something we have to worry about yet, though. The way 3D printing a house would work is by replacing human labor with 3D printing robots that would be capable of producing the floors, walls, and roofs of the house. As of now, it’s been reported that the prototypes can get all of parts these manufactured in about eight hours for a 410-square-foot house!

So, the exterior of your next house could be 3D printed by a robotic machine. The interior, like the electrical, plumbing, and heating systems, however, would still need to be installed by human workers. Then again, one theory has summarized plans for 3D printed houses that are essentially autonomous. This means that they would run on solar light, be mobile, and collect water via humidity in the air. Maybe you won’t even need the normal internal components of a house! So, if you’re wondering what it would cost you to have a house 3D printed for you, the answer, as of now, is between $60,000-$100,000 depending on the amount of space you need. If you want to try living in a completely new way, this would be a perfect place to go out on a limb and try something extremely unique!

Printing the Parts of a Car

A house is something that we use every day and essentially need in order to remain safe and survive. What about some of the other things we use every day, though? Could they end up being 3D printed at any point in the future? One of those everyday things that could potentially become 3D printed are cars. Like houses and some of the other things we have mentioned already, not every car will be 3D printed. Some, though? There’s a very reasonable possibility that many parts of cars could wind up being 3D printed and, someday, maybe even the whole car. When it comes to 3D printing car parts, however, there is as much prototyping being done as in other areas of engineering. Right now, it’s not much more than experimentation, but could grow into something revolutionary.

Industrial grade 3D printers are what help make printing car parts possible. Whether it’s a motor or, more likely, a door, these are obviously fairly large objects that would not be able to come out of a traditionally sized 3D printer. These powerful printers are capable of producing full-scale models, however, still by using ABS filament—though a much different variation than what would be used in a classroom. Much of the 3D printing that centers around car parts is simply prototyping, allowing engineers to see what works and what doesn’t. As certain things begin working, however, we could see a shift in the way cars are built—yes, just like how we could see a shift in the way houses are constructed. Similarly, 3D printing could also greatly reduce the production time and costs of cars as it continues to improve and streamline the manufacturing process.

Of course, a lot of safety tests go into building cars, so this would need to be considered as well, along with other scientific factors, like aerodynamics and wind resistance. But, like in other industries, mechanics would have an easier time if they could simply 3D print a part they needed rather than waiting weeks for it to come in. If you ask us, however, car manufacturing might be the industry that 3D printing is the farthest away from entering. It just doesn’t seem all that plausible at this point that a 3D printed car could withstand an accident and keep its passengers safe while traveling at 60 or 70 miles per hour. The concept, however, certainly is intriguing and would be a truly innovative way for car designers to maximize their resources. Even regular cars undergo scrutinizing tests before they’re made available to the public. Could you imagine how tough those tests would be for cars that were partially or completely 3D printed? We’ll have to wait and see.

For the latest EdTech, STEM, and 21st century education news, follow us on Twitter and Instagram. Like us on Facebook, too, or sign up for our newsletter for our latest product announcements and offerings. If you have an idea for an Eduporium Weekly theme, send us a message on social media or comment below.